-

Architects: Mark Frazerhurst Architect

- Area: 185 m²

- Year: 2023

-

Photographs:Simon Devitt

-

Manufacturers: Cosentino, APL door/window joinery, Abodo, Dimond Roofing, Escea, JSC Cedar cladding, Plytech, Rosenfeld Kidson Cedar screening

-

Lead Architect: Mark Frazerhurst

Text description provided by the architects. This one-bedroom house is located near the rim of a steeply sloping Auckland volcanic crater cone. Likely considered too hard to build on by most, we saw an opportunity for something great for the clients, my parents, who were looking to downsize when they purchased the empty section. The initial brief for the home contained more ’wants’ than the modest target construction budget allowed, so we challenged any preconceived ideas in order to design a home specifically for their needs, likes, and idiosyncrasies of living. Every decision with regard to design and detail was scrutinized, cost, and re-evaluated, before committing to.

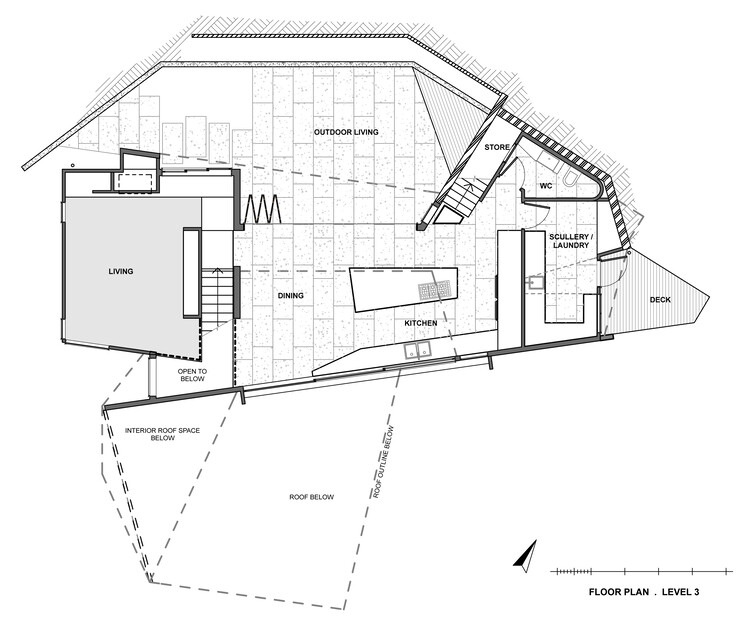

An extensive panoramic horizontal vista from the living space takes in the far side of the crater cone, as well as ‘green sea’ views of the park below. The orientation of the home and established surrounding planting provide shelter from strong North-East and North-West onshore winds from the Hauraki Gulf. The home takes its form from an element constituting both roof and wall planes, which fold down the slope, linking each level. A number of years ago, I’d seen a sculpture of a roll of corrugated iron twisting down a hillside and how the ad-hoc form created interesting spaces. We worked with this cue and designed a textural black folding form that contains and encloses spaces both internally and externally.

Timber-clad volumes anchor the folding form and contain more intimate and inwardly focused areas. We set out to design, manage, and construct the home ourselves. Design and finish quality was paramount, and the construction budget was relatively immovable, so we compromised on the only aspect we could - time. My parents and family worked tirelessly on Fridays and Weekends, calling on friends when suitable and engaging builders and subcontractors where work was outside of our abilities over a period of nine years. The house presents a continuous series of interesting moments within, where ideas have been implemented through sheer determination, passion, patience, and hard work by all involved.

Finishing materials were selected based on hand workability, adaptability, budget, handling ability, and material tactility. We approached the process and method of construction as if we could build something ourselves; we would hand fabricate parts of the building fabric on-site in smaller manageable parts (such as the cladding screens, inverted ceiling trusses, etc.) to eliminate any machine lifting. We also custom-constructed many building components from scratch on-site ourselves (e.g., doors, stairs, etc.) to reduce the overall construction cost of usually off-site fabricated elements. We made a number of cost-effective but labor-intensive modifications to relatively standard building materials, lifting the level of interest and innovation of finishes, such as routing patterned grooves in timber linings and notching holes in the subfloor cladding for subfloor ventilation. The saying “good things take time” doesn’t come close to describing this completely immersive personal project, the time invested and lessons learned, or the family bond experienced in the process in the creation of this once-in-a-lifetime home.